Call us: 08045813572

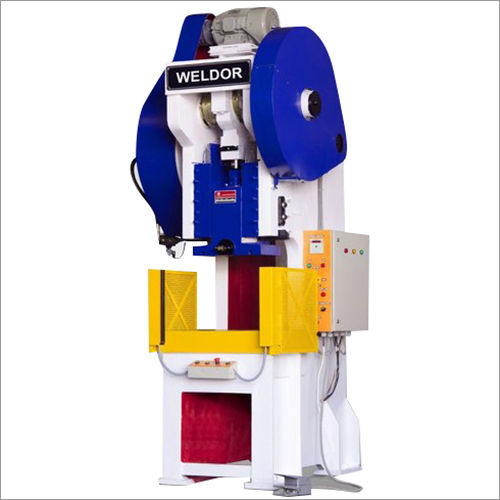

With great experience and knowledge, offering world-class Undercrank Shearing Machine, Press Brake Machine, Automatic Hydraulic Press, Industrial Press, Heavy Duty Plano Miller Machine, Hydraulic Ironworker Machine, etc.

About Us

Started business operations in 1982, we, Weldor Appliances Pvt. Ltd. are a private limited firm which has great reputation in the Indian and global markets. The company is totally efficient in manufacturing a quality assured gamut of Plate Bending Machine, Automatic Shearing Machine, Power Press, Industrial Semi Automatic Press Brake Machine, Hydraulic Ironworker Machine and other products. The components outfitted in these machines and equipment are world-class as they are sourced from authorized vendors.

With the intense desire to become a leading manufacturer and exporter globally, we are putting our best foot forward in all the tasks. We have the support of our mentor, Mr. Dhanraj Vaghela whose rich experience and sharp business acumen allow us to face the challenges and survive in this competitive world. Through his futuristic business approaches and modern ways of running the business, our company has carved a niche for itself in the international marketplace.

Why Choose Us?

We are committed to providing our clients with unmatched quality industrial machines and equipment which match international standards. Apart from our quality commitment, other reasons behind our successful position in the market are:

- Immense industry knowledge & experience

- Team of skilled and trained professionals

- Ability to deliver orders on time across the global market

- Follow ethical and transparent business practices

Brands We Deal In

Weldor is an official brand of our company, Weldor Appliances Pvt. Ltd. which is acknowledged in the market for its excellent goodwill.

Customized Solutions

- The universal 3D work benches and welding tables can easily fulfill all the horizontal and vertical requirements. In a precise and quick manner, the users can erect their systems by using modular parts such as racks, frames, railings, brackets, etc. The cost-intensive conventional devices are a thing of past. The work benches and welding tables we are providing enable the users to achieve quick, accurate adjustment and fixation of target dimensions to each workpiece their produce. During the whole process of stapling and welding, the individual weldments are clamped at the corresponding surfaces which are in the most appropriate position.

- In current days, the welding process has become more efficient with the usage of modern production methodologies. Most of the working time is being used for the arrangement of individual parts as per the exact measures & angles for measuring, adjusting and correcting. The accurate production of the components and a precise working style to develop assemblies in connection with stop elements and universal clamping enable to save time in series production as well as single part production.

- The sturdy and high load bearing welding tables are CNC machined on all the sides with a regular hole grid pattern. Because of this, all the workpieces can be infinitely positioned and clamped by using the appropriate clamping components of the system through positioning & clamping bolts on our offered 3D welding tables. Multiple 3D tables can be connected directly together on any of the 5 sides. This particular modular system fulfills versatile functions; place, clamp and fasten.

Infrastructure & Facilities

For the smooth operations of the company, we have developed a modern infrastructure facility which has advanced technologies and tools. The unit is segmented into varied departments including production, engineering, quality testing, R&D, packaging, sales & marketing, etc. For enhancing our production capabilities, we keep upgrading our installed machines & tools. Below listed are some of the facilities installed in our manufacturing unit:

- Here at our entity, we produce different kinds of Welding Tables having a hole system of 16mm and these holes are drilled using CNC machines which provide square angle grid in all the possible directions. Parts are usually created by initially placing them at the right angle to the stops on the side & front edges of the welding tables. This is highly important for maintaining right angles during the welding of huge parts & components.

- System 16 is super beneficial for providing multiple holes in a particular given area for all the accessories get clamped.

- Generally, welders get irritated due to unavoidable welding spots & spatter available on the platform surface that develops bumps which are hard to remove.

- The modular welding tables make it possible to design & develop the most diverse & customized table surfaces by using only few components. The surface of the table can be opened for accommodating protruding parts.

- The individual plates of the table surface having the tolerance ability upto 0.05 mm thus, they can be interchanged.

- Accessories such as riser blocks and extension blocks can be utilized to extend the perimeter of the table to accommodate huge components & parts.

- Oscillating sheets are smoother because of the deep countered holes over the table which allow counter sunk high tensile bolts to flush with the table surface.

Customer Satisfaction

Our business enterprise has managed to become the preferable choice of the customers by supplying best quality Industrial Semi Automatic Press Brake Machine, Hydraulic Ironworker Machine, Power Press, etc. from the past several years. We share strong and long-lasting relationships with our valuable clients who are associated with us from so many years. Through regular interactions, we try to understand their exact requirements and produce the goods accordingly.

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese